Any product, if designed, engineered and manufactured correctly, serves its life span. We at Ensys follow this principle to the core.

Our Manufacturing plant has all the latest technologies and equipment to assemble the Heat Pumps. The entire manufacturing team is skilled and well trained.

Quality Management

“At Ensys, quality is our topmost priority at every stage of manufacturing. This starts with receiving material inspection, followed by assembly, vacuumizing the copper piping, and leak testing of joints, culminating in a comprehensive performance test. Our engineers and technicians are fully trained to maintain a keen eye on quality, ensuring the desired performance of every product.”

"All product claims need to be tested; we have designed a special test bay to test all Heat Pumps for several parameters.”

It is crucial to test the Heat Pumps once they are assembled. This not only ensures performance but also verifies that the refrigerant gas profile at every stage of the working cycle meets design parameters and remains within the compressor envelope. These tests are essential for the long life of the Heat Pump.

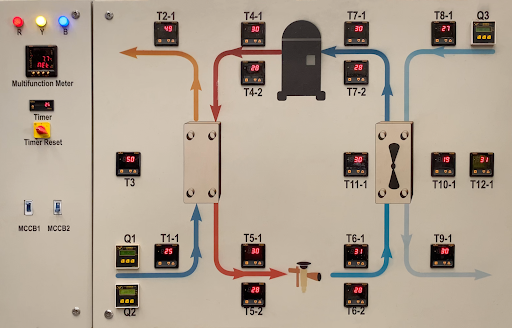

“At Ensys, all Heat Pumps are tested at a specially designed test bay to ensure their parameters meet our high standards. A PLC-based control panel is installed to conduct comprehensive tests, including:

- Utilizing a 1000-liter storage tank

- Monitoring all temperatures and pressures at every stage of the working cycle

- Measuring actual power consumption with an energy meter

- Ensuring the desired flow of water with a flow meter

- Checking power factor correction with a power factor correction meter

With the collection of above data, our claims of COP (Coefficient of Performance) are thoroughly tested and proven, ensuring the efficiency and reliability of our heat pumps."